Temperature-Controlled Shipping Solutions

Ensuring products remain consistently cold during shipping is paramount, especially in the healthcare and food sectors. Our temperature-controlled solutions offer dependable means for shipping a variety of goods, including life science products, food items, chemicals, and beyond.

Utilizing ThermaBrick® Refrigerant Bricks ensures the precise temperatures and security required to comply with cold shipping regulations, thereby preserving the quality of your products throughout transit.

Customizable Cold Chain Packaging

ThermaBrick® Refrigerant Bricks provide customizable shapes with safe, multi-purpose, and cost-effective cooling capacity, allowing customers to ship in just the right-size box with refrigerants that minimize box weight and dunnage.

Companies seeking superior end-user experiences can rely on Temprecision International for cold chain solutions in custom-shaped refrigerant bricks. Through technical and regulatory support, we minimize risk and match your temperature-controlled packaging needs with a customized product delivered on your tight timeline.

ThermaBrick® Refrigerant Bricks are cost-effective, passive refrigerants that are customizable to any size and shape, and designed to reliably maintain your cargo’s temperature.

How ThermaBrick® Refrigerant Bricks Protect and Maximize your Payload

- Offers cost-effective cooling capacity

- Available in any dimension to eliminate dunnage

- Maintains stack-ability

- Most efficiently optimizes the contents of a container to minimize box weight

- Printable with your company logo

- The foam absorbency actively masks most leaks and punctures

- Easily customizable to optimize packout

- Safe and effective coolants for temperature-controlled packaging

- Targets dimensional weight pricing strategies

- Full portfolio of phase change materials (PCMs) to meet subzero, refrigerated, and control room temperature applications

Cost-effective alternative to:

Dry Ice requires a shipper to handle using personal protective equipment (PPE), actively manage the inventory/sublimation-loss, and print and apply costly hazardous materials labels. They can also potentially face fines.

Gel packs offer cheap refrigerants but cost significant payload capacity. They also have the potential to leak.

Rigid plastic bottles are costly and have an initial high carbon footprint that reduces coolant capacity. They promise reusability but often don’t offer a return program.

Cold Shipping Solutions Across Diverse Industries

Our temperature-controlled packaging products stand unrivaled, meticulously crafted to cater to diverse needs across various industries.

Life Sciences

ThermaBrick® Refrigerant Bricks ensure the safe delivery of precious life science products around the globe. We offer best-in-class components for healthcare logistics products specifically developed for:

- Pharmaceuticals

- Biotechnology

- Blood

- Diagnostics

- Human tissue specimens

- Clinical trials

- Dispensaries (mail-order pharmacies)

- Home healthcare

- Medical devices

Our science-driven life sciences solutions are backed by 20+ years of cold chain experience, cGMP and ISO certification, global coverage, rapid customization, and global research by our technology team.

Shipping Cold Food

No matter if your goods require refrigeration or freezing, we can tailor our cold shipping solutions to your requirements. Whether it’s cheesecake, chocolate, confections, seafood, meats, or cheeses, we provide pre-qualified market-ready solutions or personalized engineered alternatives.

Partnering with Temprecision assures enhanced performance and innovation. Whether opting for standard or custom solutions, our cold packs for shipping food are designed to fulfill your unique food shipping needs.

Chemical Shipping

Our best-in-class shipping solutions are specifically developed to deliver various chemicals and keep your products at a consistent temperature from production to delivery. We work with industry leaders to deliver low-cost, high-power products to support safe delivery of chemical and diagnostics products around the globe.

Logistics

ThermaBrick® Refrigerant Bricks ensure safe and compliant transportation to wholesalers, hospitals, clinics, and retailers. We help shippers focus on maintaining revenue streams and delivering temperature-sensitive products across various applications, optimizing shipping efficiency. Backed by over 20 years of experience, cGMP/ISO certification, global coverage, and rapid customization capabilities, Temprecision International stands as a trusted partner in cold chain logistics.

ThermaBrick® Refrigerant Bricks Properties

ThermaBrick® Refrigerant Bricks are designed to maintain shape during freezing-thawing or transit and are used by companies throughout the world where reliability and efficiency are top priorities. ThermaBrick® Refrigerant Bricks perform up to the cold chain industry standards and commonly exceed customers’ expectations for passive temperature-controlled solutions. At Temprecision International, our focus is on maintaining the consistent quality of our products while delivering innovative cold chain solutions to our customers.

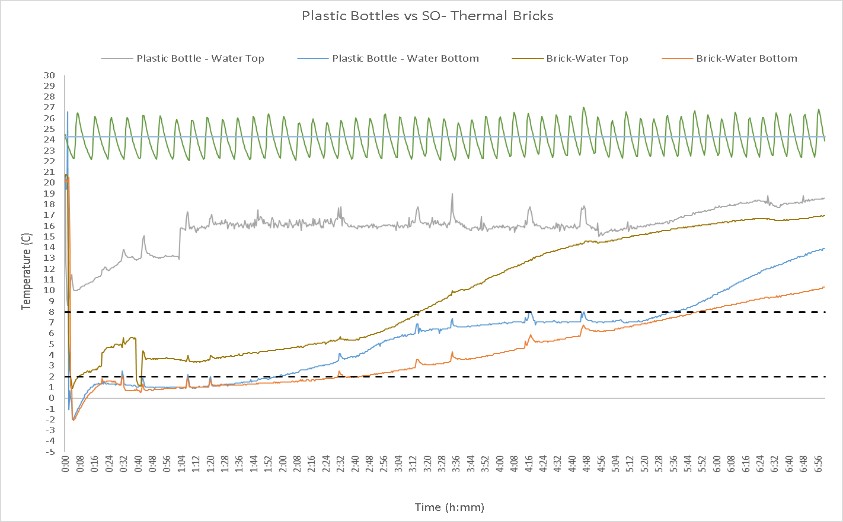

ThermaBrick® Refrigerant Bricks excel in maintaining consistent temperatures and outperform traditional gel packs and fluid-filled bottles.

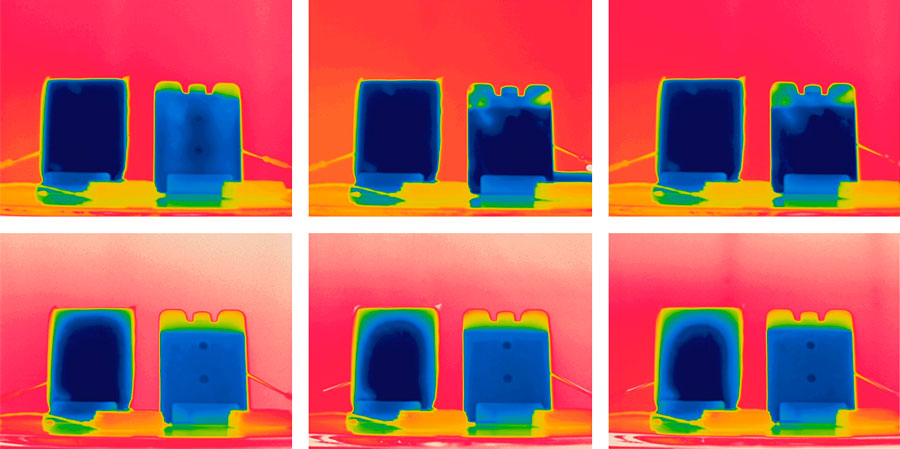

During testing, each ThermaBrick® Refrigerant Bricks undergo rigorous conditioning at -19˚C for 48 hours to ensure reliability. During our precise testing process, the ThermaBrick® Refrigerant Bricks are vertically aligned in a controlled environment set at 25˚C with 50% humidity. We use advanced infrared imaging to monitor heat transfer, ensuring the highest standards of quality and performance.

Equipment: FLIR Camera, TEMPTALE Sensors

Results demonstrate the surface temperature of the ThermaBrick® Refrigerant Bricks used in the product testing exhibited a more uniform temperature across the surface and held a more consistent temperature longer than the fluid-filled plastic bottle.

See time and temperature data plotted below from the sensors.

Phase Change Materials, known as PCM, are formulated to change phases at specific temperatures, providing cold chain management at just the right temperature to protect your payload and offer consistent cooling throughout the duration of shipping. Whether you require subzero, ambient, or control room temperatures, Temprecision International has the cold chain solution for you.

We offer a complete range of Phase Change Materials to meet any need and continually innovate new solutions to match our customers’ needs.

Subzero

- PCM-21

- PCM-10

Refrigerated

- PCM0

- PCM+5

Control Room Temperature

- PCM+18

- PCM+22

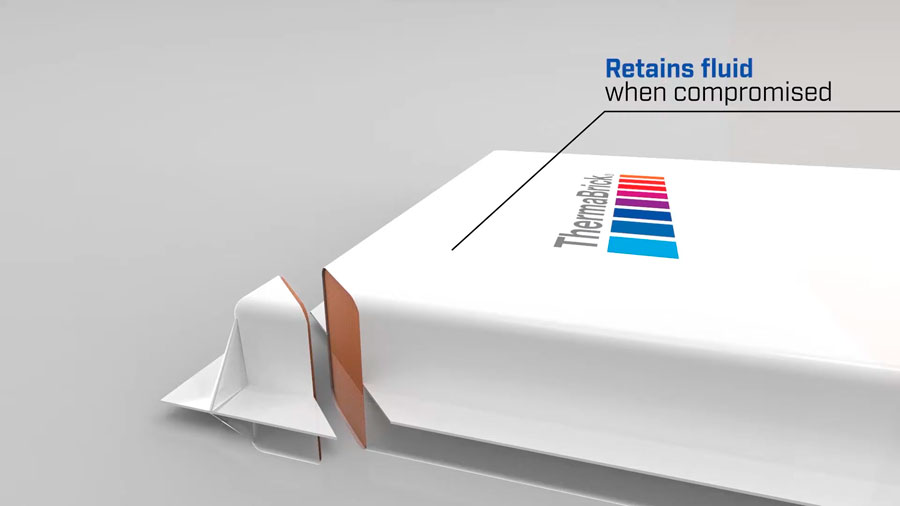

With 95% or greater absorption efficiency, ThermaBrick® Refrigerant Bricks will not melt or lose fluid if compromised. Unlike alternative products, if the outside is compromised, the majority of the fluid (PCM) will be retained inside the ThermaBrick® Refrigerant Bricks.

ThermaBrick® Refrigerant Bricks can be customized to the exact size you need for your specific application without the cost of expensive tooling, allowing your customer to maximize the space available for their temperature-assured cargo.

While internal payload volume increases, exterior volume is held constant. This allows the users a decrease in corrugate or box purchases, and, at the same time, a decrease in logistic costs associated with shipping and maintaining the temperature ranges of that cargo.

Temprecision® Foam has been engineered to meet our customer’s strict absorption requirements and can absorb 95% to 99% of a fluid in a matter of seconds.

PCM-21, PCM-10, and PCM0 ThermaBrick® Refrigerant Bricks are non-toxic, designed for use in food-grade applications, and are printed with a disclaimer for clear communication to consumers. Toll manufacturing and custom printing are also available.

Customizing ThermaBrick® Refrigerant Bricks specific to your application allows you to maximize the internal cargo payload size.

The maximization of the internal cooling capacity and its associated volume with ThermaBrick® Refrigerant Bricks allows for maximum volume achieved for the temperature-assured cargo.

Internal payload volume increases, while exterior volume is held constant. This allows for a decrease in corrugate or box purchases, and, at the same time, a decrease in logistic costs associated with shipping and maintaining the temperature ranges of that cargo.