The cold chain logistics industry is vital for transporting and storing temperature-sensitive materials across various sectors, including pharmaceuticals, food, chemicals, and biological materials. Effective cold chain solutions ensure the integrity of these products by maintaining specific temperature ranges throughout the supply chain. For industries like life sciences and healthcare, reliable temperature-controlled packaging is essential to prevent spoilage, financial losses, and health risks.

The Importance of Cold Chain Management

Effective cold chain management is the backbone of transporting temperature-sensitive materials, ensuring they arrive at their destinations in optimal condition. For instance, the pharmaceutical industry suffers annual losses over $15 billion due to temperature excursions during transit.

Key industries rely on temperature-controlled packaging to meet unique requirements:

- Pharmaceuticals and Biologics: Maintaining precise temperatures is essential for vaccines, lab samples, and medications.

- Food: Preventing spoilage and contamination during transit protects both revenue and consumer health.

- Chemicals: Sensitive chemical compounds require strict temperature control to preserve functionality.

By prioritizing cold chain management, industries can mitigate risks, minimize waste, and safeguard product quality.

Understanding Cold Chain Solutions and Management

Cold chain solutions leverage specialized logistics systems and temperature-controlled packaging to maintain stable temperatures during transit, essential for overcoming challenges such as:

- Temperature Fluctuations: Products may encounter extreme environmental conditions during shipping.

- Regulatory Compliance: Adhering to international standards like ISTA and AFNOR is crucial for ensuring product safety and efficacy.

- Efficient Transportation: Coordinating transportation across regions demands robust systems to avoid delays and maintain consistency.

With precise cold chain solutions, businesses can minimize losses, optimize efficiency, and maintain customer satisfaction.

Key Questions for Cold Chain Logistics

- What temperature ranges are required for your products?

Products may require frozen, chilled, or controlled ambient conditions. For example, pharmaceuticals like vaccines and biologics often must be stored between 2°C and 8°C, while meats require refrigeration below 4°C. - What environmental conditions will shipments encounter?

Seasonal and geographical profiles impact shipping performance. Shippers must handle fluctuating temperatures while maintaining stability within agreed-upon ranges, whether frozen or controlled ambient. - What management strategies will you employ?

Implementing monitoring systems, pre-shipment testing, and robust contingency plans are critical for ensuring smooth operations in cold chain logistics.

Answering these questions ensures better alignment with cold chain management goals.

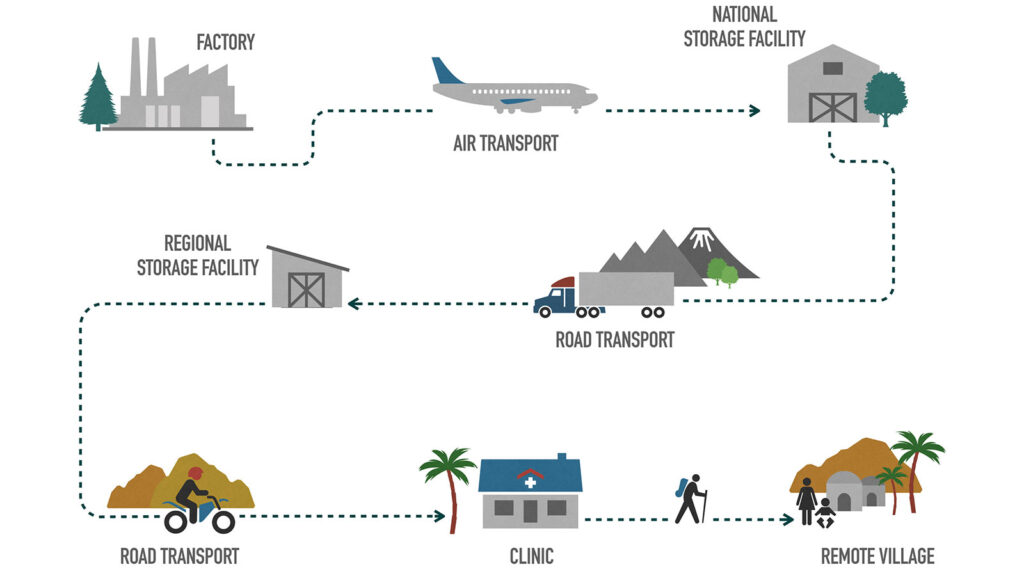

The long road to vaccination

Vaccines must be kept between 2–8ºC all the factory to some of the most remote places on Earth

3 Main Types of Temperature-Controlled Packaging

Cold chain packaging can be categorized into three main systems:

- Active Systems: Utilize external energy sources (e.g., refrigerated trucks) for continuous cooling but are limited by energy dependency and route constraints

- Passive Systems: Leverage phase change materials (PCMs) for temperature stability without external energy. These systems are cost-effective and highly flexible

- Hybrid Systems: Combine the benefits of active and passive systems by using PCMs alongside powered cooling systems for extended durations

Choosing the Right Refrigerant Solutions

Selecting the ideal cold chain solution for your needs requires balancing efficiency, reusability, and environmental impact.

Traditional Refrigerants

- Dry Ice: Effective for subzero conditions but non-reusable, requiring special handling and hazardous materials labeling (Passive System)

- Rigid Plastic Bottles: Reusable but come with high tooling costs and a significant environmental footprint (Hybrid System)

- Ice Packs: Inexpensive but prone to leaks and lack shape stability, leading to inefficient temperature control (Passive System)

ThermaBrick® Refrigerant Bricks

ThermaBrick® Refrigerant Bricks are a flexible, reusable solution optimized for cold chain packaging.

- Maintain consistent temperatures from -21°C to 22°C using advanced PCMs

- Reduce leaks with foam-based construction and enhance efficiency through customizable sizing

- Suitable for both passive and hybrid systems, delivering sustainability and reduced operational costs

Learn more about how ThermaBrick® Refrigerant Bricks compare to traditional refrigerants.

Streamline Your Cold Chain Management

Cold chain logistics requires innovative solutions to protect temperature-sensitive materials. Temprecision International’s products, including ThermaBrick® Refrigerant Bricks and Temprecision® Foam, provide reliable, sustainable solutions for your unique shipping needs.

Contact us today to learn more about optimizing your operations with advanced cold chain packaging solutions.